We supply casting for Aerospace Industry

For the Aerospace Industry castings are vital. No plane can lift off and no rocket may move into space without casting. Casting components are required in turbines and jet engines as well as in the fuselages, undercarriages and interior fittings of airplanes.

We supply casting for Automotive Industry

To work with any automotive machine casting is essential. Castings are used in vehicle engines, drivetrains, and chassis but also in vehicle bodies as well as the large machinery required to manufacture the vehicles.

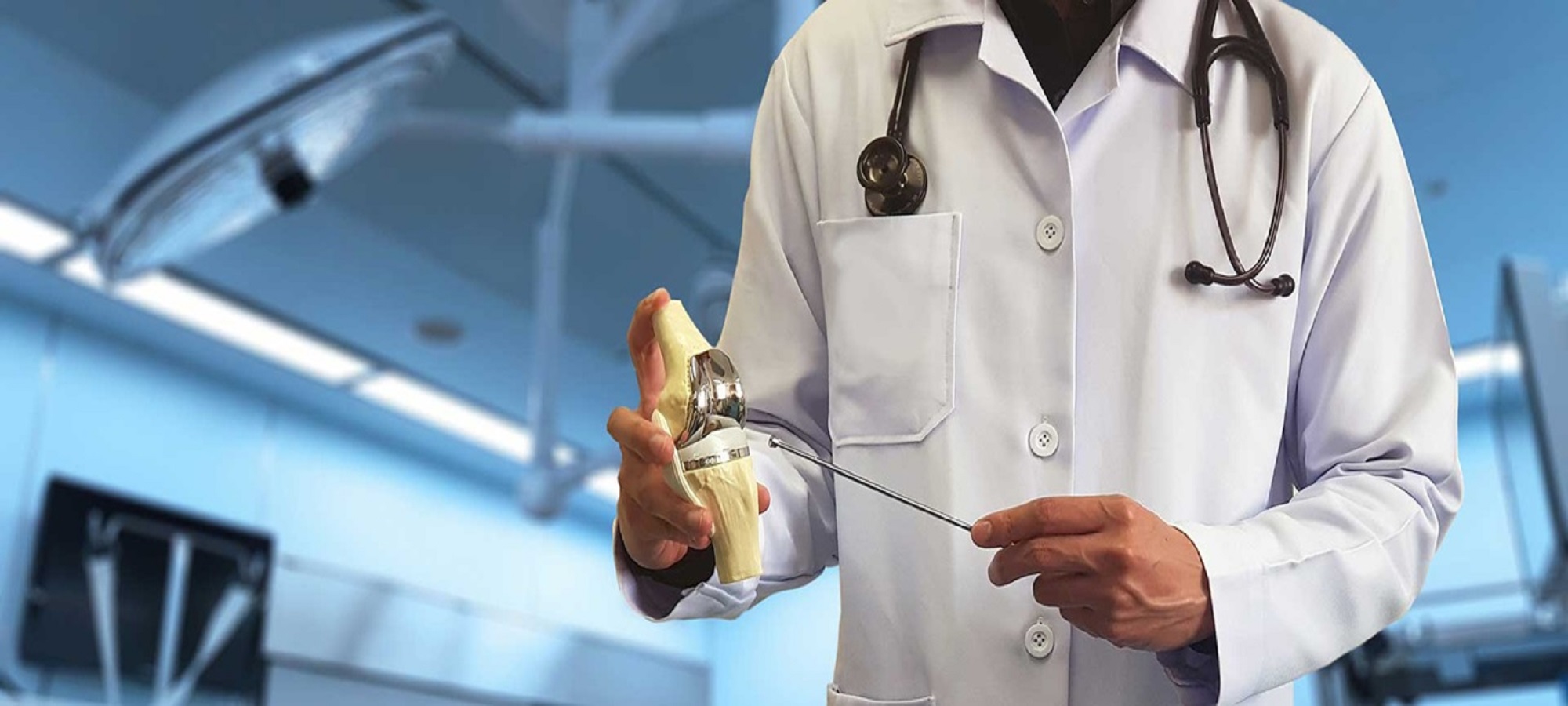

We supply casting for Medical Sector

Because of casting most people live a new life with the help of a doctor. Casting has an essential role in the medical sector as it is used in medical machinery like scanners the bed nodes as well as for cast prostheses like knee and hip joints.